Introduction

One of the most common causes for a particle counter not performing to specifications is sensor contamination or, otherwise, not having an adequate PM (Preventative Maintenance) program.

Calibration

When Climet performs an interval calibration, your technician conducts the following preventative maintenance activities: FCR (False Count Rate) Testing. FCR Testing is a compulsory test required by ISO 21501-4. If the instrument fails FCR (False Count Rate) testing, it is a leading indicator of sensor contamination.

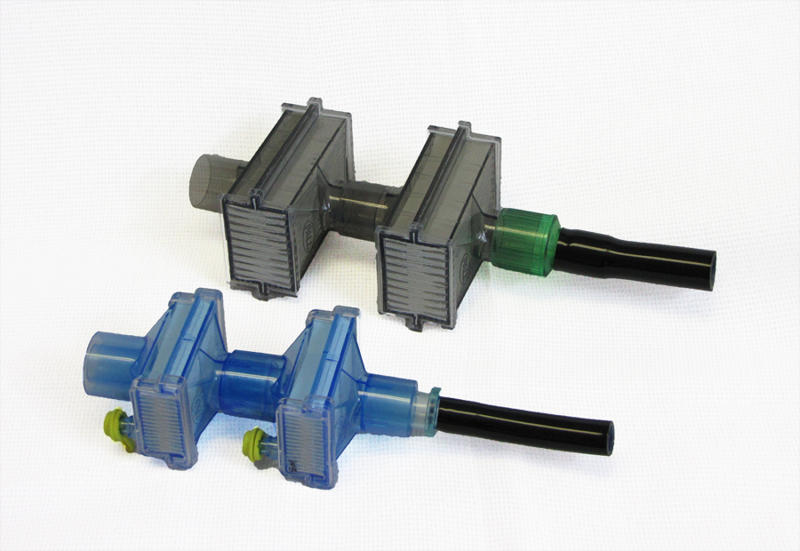

Purge Filters

Purge Filters, also known as Zero Count Filters, can potentially cause sensor contamination. The inside of each double-stack contains HEPA filter material, and the case itself is plastic.

Dropped Filter: Whenever a zero-count filter is accidentally dropped, it should be immediately discarded and replaced with a new filter. A dropped filter almost always damages the internal HEPA filter material. Alternatively, the plastic case may crack, resulting in leaks that can provide counts during a Purge Test.

What about testing a dropped filter? This is not recommended. Once the HEPA filter material is catastrophically damaged, testing a damaged Purge Filter will, with a moderate to high probability, contaminate the particle counter used to test the filter. Testing of the Purge Filter should only be performed by Climet factory technicians. However, the cost of conducting a HEPA Filter test will exceed 50% of the purchase price of a new filter. Therefore, Climet generally recommends immediately discarding dropped Purge Filters.

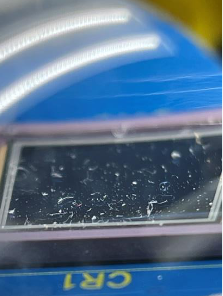

Even a single invisible fibre from a damaged Purge Filter can become lodged in the sensor block, resulting in false counts. Severe sensor contamination can result from a severely damaged Purge Filter, which can contaminate the sensor block and, as shown below, the instrument’s photodetector and inlet:

Climet recommends that dropped Purge Filters be immediately discarded and replaced. There should also be a preventative maintenance program to replace used Purge Filters every 3-6 months, and not more than every 12 months.

Inlet Cap

As part of a PM program, the inlet of a particle counter that’s not in use must be capped to prevent particulate contamination from entering the sensor. This may require personnel training.

Indeed, many particle counters sent to Climet for an interval calibration arrive without inlet caps. As a standard operating procedure, instruments sent to Climet for calibration that do not have an inlet cap will have one installed by your Climet technician free of charge. If additional inlet caps are needed, please email service@climet.com.

Routine Sensor Cleaning

Climet does not recommend customers order a sensor cleaning during the interval calibration unless your Climet technician advises.

A False Count Rate (FCR) test is part of an ISO 21501-4 compliant calibration. This test will confirm if these is sensor contamination. If so, your technician will advise accordingly. Moreover, if a proper PM program is in place, the probability of sensor contamination is significantly reduced.

Resolving Sensor Contamination

If, during the Purge Test, there are excessive counts or count bursts, the best way to resolve sensor contamination is to:

- False counts into the millions, particularly in the lowest channel size, have frequently been confused with sensor contamination. The root cause is likely a result of fluorescent light entering the sensor chamber. Climet recommends using a Light Blocker Isokinetic Probe directly placed on the inlet. Alternatively, place a small bend in the sample tubing to block light from entering the sensor chamber. For further information, refer to Application Note #161108 (Isokinetic Sampling and Types of Probes); and Application Note #172401 (Sample Area Lighting).

- Install a new Purge Filter, then tap the inlet to knock free particles that may be sloughing off of the inlet during the test. Continue to tap more forcefully until there are no more count bursts. Be careful not to damage the inlet.

- Install a new Purge Filter and run the particle counter continuously overnight. This may resolve the issue. In the morning, conduct a Purge Test (Ref. Application Note #171302 and Climet’s Best Practices Guide).

- If still unable to clear the excessive counts or count bursts, contact a Climet Applications Engineer to obtain an RMA number for a factory sensor cleaning and re-calibration.