Ensuring a controlled environment and quality consistency are important when we talk about environmental monitoring; this is especially true when it comes to emissions testing, a critical aspect that ensures the exhaust air from a monitoring apparatus does not compromise the integrity of the environment being sampled. We will be unravelling the significance of emissions testing, shedding light on the role it plays in maintaining the purity of clean areas, particularly in aseptic operations.

Environmental monitoring equipment, including particle counters and microbial samplers, is designed to safeguard the controlled environments they operate it. The exhaust air from these devices must not introduce contaminants or be re-aspirated into the sampling apparatus. To achieve this, a key element comes into play – the incorporation of a High-Efficiency Particulate Air (HEPA) filtered exhaust.

Understanding particle counters and microbial samplers

Particle counters and microbial samplers are equipped with components that have moving parts, generating friction in the process. Unfortunately, this friction can lead to an increased particle burden in cleanrooms due to the generation of inert particles. Recognising this challenge, manufacturers have implemented innovative solutions to address emissions concerns.

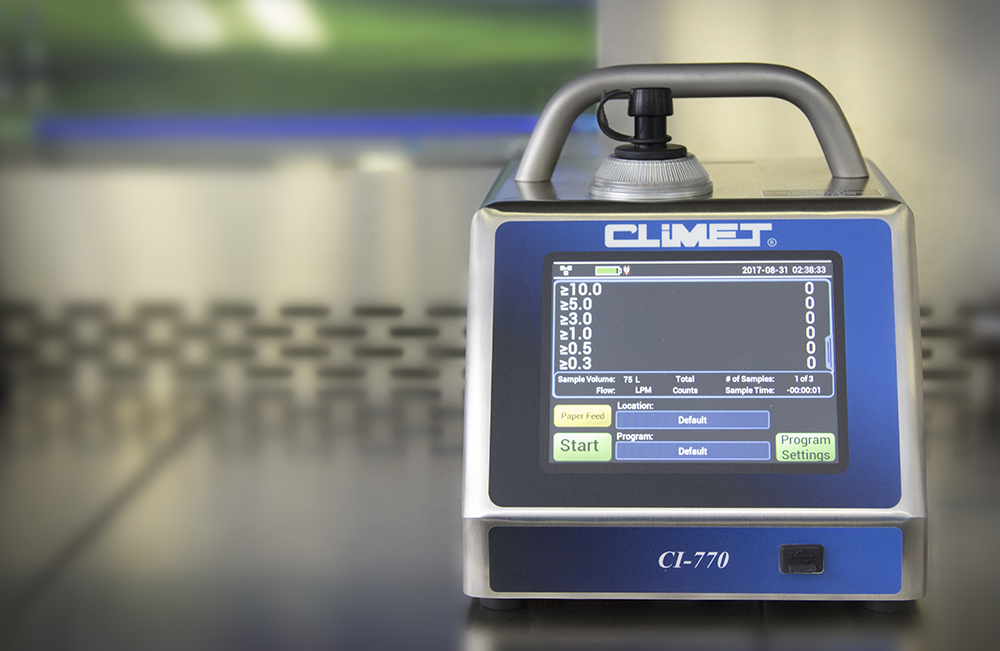

The CLiMET advantage

What sets CLiMET apart is its meticulous approach to emissions testing. Unlike many counterparts, CLiMET particle counters are engineered to incorporate a unique feature – the exhaust airflow first passes a HEPA filter before being discharged through the back panel.

The emissions from CLiMET particle counters undergo rigorous testing during the manufacturing process. This evaluation ensures that each instrument meets the stringent requirements for an ISO Class 3 cleanroom environment. ISO Class 3 standards dictate up to 8 particles 1 µm in size per cubic meter of air, and as such, making it a critical benchmark for industries.

CLiMET is the sole particle counter manufacturer that certifies exhaust emissions to ISO Class 3 on every new production particle counter and microbial air sampler. This certification process reaffirms CLiMET’s dedication to providing monitoring equipment that not only meets but exceeds industry standards.

As industries continue to prioritise cleanliness and contamination control, the role of emissions testing in monitoring equipment becomes increasingly crucial, setting the stage for a future where precision and reliability in environmental monitoring are all the more important.